The Olympic Peninsula Branch

Thursday, December 25, 2025

Sunday, August 10, 2025

Seize The Day

You have probably heard this phrase before, whether it was in a movie, song lyric, or advice from someone, perhaps a teacher or mentor. The original Latin phrase “carpe diem” literally translates to “pluck (or harvest) the day.”

In any case, the expression is often used to suggest that we do not wait, but rather do the things we want now rather than later. Take action, enjoy life, make a move while we can. In the railroad modeling hobby, many of us can relate to delaying our dreams or hobby aspirations due to other priorities in life, only to find that opportunity has passed us by. In the larger sense, this might be health, vision or fine motor control or resources. As I approach retirement these factors are coming into focus (pun intended). Fortunately, I am still physically able to perform, and even improve on, the skills for detail work on HO scale prototype models and also am fortunate to have the resources to (usually) obtain what I want, for the time being anyway.

Currently I have accumulated much more than I have built in terms of models, adding many “to be built” kits and detail parts to my stash over the last few years. In some cases, these are limited release or out of production craftsman kits that have been “seize the day” purchases.

Archer resin printed surface details are once again available, after a short hiatus when the original owner sold the business, leading to much angst in the prototype modeling community. This seems to be much more the exception than the rule, however, given the hurdles of finding a buyer for a small scale business.

I was reminded of this just this morning, when I learned of the closure of Custom Model Depot, which stopped producing last year. This family run business offered a range of 3D printed model railroad items, including the Dalman Andrews trucks pictured above. In this case, I did purchase several sets of these when they were announced, since they are a “signature” freight car truck for the Great Northern. The business closed due to demands of work and limited free time.

Running a business is challenging, requiring a great deal of effort, time and money. For hobbyist type producers, unless a large established manufacturer with a range of items with broad appeal, their enterprise is frequently a labor of love as opposed to paying the bills. As a result, burnout, everyday life or changes in circumstance play a part in the short life of many suppliers. Some do last, but even so their products are commonly limited production runs. All the more reason to seize the day when possible.

In the event one misses the original availability of a limited run kit or other item, not all hope is lost. In person swap meets and online marketplaces such as eBay, or forums like HOSwap on IO , as well as specialty online retailers, can be viable sources of out of production items.

Patience is a virtue when seeking out a specific car or other item of interest that is no longer manufactured, unlike the near instant gratification of buying when a kit is first available. It can take months, even years, to find something that is long out of production. I have learned to ask around in the modeling community, as you never know what someone else has in their stash that might be just what you want. In some cases, trades can be worked out that benefit both parties, allowing us to get value from our surplus. Learning how to set up targeted saved searches on eBay is another way to hunt for a sought after item.

The warehouse kit and the “Roof Topper” shown above are both the result of literally multi-year searches waiting for these items to show up from a seller. In each case, I had seen these advertised when they were first offered, but put off buying for one reason or another only to find that the manufacturer had shuttered operations when I finally had the resources to move ahead. Scouring hobby shops and swap meets was fruitless, but online searches finally paid off after a few years. The waiting does ensure that the sought after item is REALLY wanted.

The New Rail Models Bingen Loading Warehouse is a unique signature structure on the SP&S (now BNSF) rail line through the Columbia Gorge in Washington state and fits with my time period and wood products focus. I have driven by the actual warehouse in Bingen while traveling on Highway 14 through the Gorge many times. While the model is selectively compressed, it captures the unique look with curved roof and large exposed tresses. Perfect for a loading siding with stacks of plywood or lumber and offering a good reason for all the double door box cars in my stash!

Seeing the Great West Models Roof Topper ads years ago inspired an idea for a small chemical plant scene with a distinctive but relatively common arched industrial roof shape, particularly in the coastal Northwestern US, where abundant rain makes flat roofs problematic. Again, this is a roof style I have observed frequently in work travel over the years. These roof moldings were offered in several sizes intended to modify several different common HO building kits. The one I sought is for the City Classics Carnegie Street Manufacturing building kit, adding visual interest and a change from the standard look. Many pulp and paper mills in the Northwest had small specialty chemical manufacturing operations associated, as I have discussed before https://olympicpeninsulabranch.blogspot.com/2025/03/prototype-inspiration-chemicals-and.html More reason to build all those tank car kits I have been accumulating.

I have had similar success searching for out of production freight car kits that caught my interest or filled a specific desire, often after significant time waiting. With time and searching it is possible to locate that prize you missed the first go round in many cases. There are still a few on my list! The easiest and quickest path though is to pluck the day when you first see that beauty you want, if it fits your budget.

-Carpe Diem

Sunday, March 9, 2025

Prototype Inspiration - Chemicals and The Paper Industry

The Northwest has a long history of forest products production, from timber and plywood to paper, providing many carloads of revenue for the railroads serving this region. Pulp and paper mills have always held a great fascination for me, particularly the large integrated mills which started with logs or raw wood chips and carried out every step of transforming the wood into finished products. I’ve been fortunate to spend a good part of my career selling equipment to these mills while learning their processes and history.

Some of the first pulp and paper mills in the Northwest were established in the late 1800’s and early 20th century. Many expanded and diversified over time to become very large manufacturing enterprises. What many do not realize is that the pulp and paper manufacturing process requires a great deal of chemistry, as well as producing some useful chemical byproducts.

While the first paper making process was mechanical, chemical pulping followed, producing a wider range of more useful and attractive paper products. There are several basic processes to break down wood fiber into pulp that can be used to make paper of many types. These processes can require caustic, acids, lime, bleaching agents, mineral slurries and other specialized chemicals. Additional chemicals are used to provide specific properties for finished paper products, such as brightening agents, rosin and starch for sizing, mineral slurries like clay for smoothness, even copper sulfate as a fungicidal additive (for fruit wrap), among others.

The Kraft, or sulfate process, is the dominant method used (https://en.wikipedia.org/wiki/Kraft_process), with the sulfite process (https://en.wikipedia.org/wiki/Sulfite_process) and it’s variations not uncommon in the heyday of paper production. Here is a good basic article on papermaking chemistry: https://www.chemistryworld.com/features/the-complex-chemistry-of-making-paper/4017234.article. Other specialized methods combine temperature and pressure with chemicals or mechanical processing. It’s not my intent to provide a treatise on papermaking, but to illustrate the range of chemicals consumed, and transported by rail, in this industry.

At various times, liquid byproducts from pulping were commercially attractive to market as well. These included tall oil, wood alcohol, turpentine and lignin compounds. Another was vanillin, artificial vanilla, produced from lignin, refined and sold for flavoring.

All, or most, of these chemicals require tank cars, or sometimes box cars with bags or drums, for inbound and outbound loads.

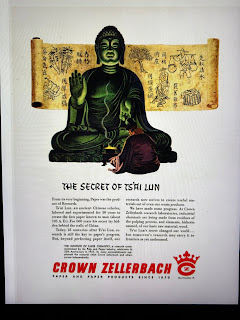

The photo in the advertisement above shows an overview of the Puget Sound Pulp and Paper mill in Bellingham, Washington. A string of tank cars and the curved chemical area railroad tracks are visible in the mid foreground of the picture. This mill is a primary inspiration for my layout modeling efforts. During World War II it produced wood alcohol along with other chemicals, and owned a small second hand fleet of private label tank cars, apparently until the mill was sold to Georgia Pacific in 1963. My research on these cars continues, with the goal of modeling them.

The mill received tank cars of chlorine for bleaching, sodium hydroxide and sulfuric acid for the pulping process, along with other papermaking chemicals. All of this provides opportunities to model a range of tank cars suited for these commodities. I will expand on this in subsequent posts and as my research progresses.

Sunday, January 5, 2025

New Year, New Tools

I am always curious about the tools people have on their modeling workbenches, looking for ways of doing things better or with more precision, as well as adding new skills to my repertoire. Regularly, I discover items of interest so I keep a running list of possible additions and their source. Near the end of the year, I purchased several new tools from my list, illustrated below. Some were based on experience using less suitable tools, others intended to expand my capabilities.

At the top is a pair of heavy duty flush cut pliers from FastCap. These are primarily intended for clipping trip pins off Kadee couplers as close as possible. They can also be used for heavier brass wire. I have been dissatisfied with my other diagonal cutting pliers as they leave a significant nub. This was an Amazon find, a return at a substantial discount, appearing unused.

The metal blocks on the right with the rows of holes are machinists parallel blocks, or 1-2-3 blocks, with precision machined right angle faces. These are helpful for providing support and ensuring right angles when attaching boxcar or building sides together. The blocks can also provide weight for holding parts together while gluing. I found these at Amazon.

Recently, several expert railroad modelers shared about their use of The Glue Looper, an ingenious applicator for thin CA glue. I had been using wire, toothpicks and an etched brass applicator from Eduard, with mixed results. The photo shows one of the Glue Looper tips in a green hobby knife handle, along with the packet of tips in three “sizes”, referring to the size of the loop and how much glue it holds. The tip is selected based on the length of the glue application. I have already used a medium tip and am very happy with the precise application and ease of use. The handle was purchased with the tips as an option, but any hobby-knife holder should work. I wanted a dedicated handle and the bright green color stands out.

The rectangular metal piece with two black knobs in the center of the photo is a photo etch elbow bender from UMM-USA (Unique Master Models). John Vojtech is a highly skilled master modeler who offers an extensive range of tools, supplies and models on his website. John has also developed some excellent tools that he has custom made, including photo etch benders. These particular designs are well suited to bending brass for etched ladders and long narrow shapes such as door tracks. He offers a number of versions, including 60 (MN004) and 150 millimeter (MN014) length models that include a bending brake. I had the 60mm bender on hand, purchased for etched ladder stile bending, and wanted a longer one specifically for a few upcoming projects where I plan to make door track angles from thin sheet brass.

Again, these tools come highly recommended by several prolific railroad modelers. As standard, the benders have Allen head screws for clamping. Some folks have modified them with M6 star knobs purchased separately for ease of use, not requiring a hex wrench. The knobs are readily available online at Amazon.

While at the UMM website, I discovered another tool developed by John, a scriber. There are several versions, designed for scribing panel lines on aircraft models but having utility for other purposes as well. I purchased the SCR-03 “third generation” universal scriber to use for scraping and scribing in confined areas. It is a thin dual ended chisel type tool made of hard tool steel with one side also having a sharpened edge well suited to scribing on curves. The hook shaped end looks particularly useful. This tool is shown in the first picture, at the lower left. I was reminded of some of the dental tools that have a similar shape and this tool seemed like it might find good use. An impulse buy so we shall see how it goes.

Did I absolutely need all of these new things? Possibly not, but working with well crafted tools that are built for purpose makes modeling more enjoyable for me, and elevates my game. At least, this is what I tell myself!

Thursday, December 26, 2024

Sunday, December 22, 2024

Resin PRR X37 Build, continued

Continuing with a detailed step-by-step description of this resin boxcar build. The trucks and decals I ordered for this project arrived, as well as some 1/4 ounce wheel weights. The photo below shows these and some other details that I intend to substitute for, or add to, kit furnished items.

From left to right, a Tichy AB brake set will be used for the underbody brake detail, 1/4 ounce stick on wheel weights as needed on top of the floor, will likely use a Detail Associates Equipco brake housing (#12 on sprue), Branchline 7 rung ladders are a close match for the prototype after being cut down to 6 rungs, and a Kadee Equipco brakewheel is in the upper middle. The Bowser 2D-F15 coil elliptic trucks with steel wheels per my research, Yarmouth #220 etched brass sill steps for GSC tank cars will be modified for the corner sill steps, and Microscale set 87-1201 for the lettering with Shadow Keystone heralds round out most of the major enhancements. I realized after the fact that I did not include the airhoses and brackets from Hi-Tech Details or the coupler lift bars (Tangent) in my photo.

I have not yet decided whether I will use the resin “wood” running board from the kit, or substitute a Yarmouth laser cut wooden running board set. In addition there are a few other items such as bracket grabs (Kadee or Red Caboose) and wire that will be used. More description on these as I progress.

In my last post, I had test fit the floor into the one piece resin body after some careful sanding on the edges of the floor casting. The fit is very snug and I was concerned about pressing the floor all the way on. It was suggested that I drill and tap the bolsters for the trucks so that the screws could be used to help remove the floor.

The first step in doing so was to measure and locate the centers for drilling the bolsters using a small metal rule to check from side to side, verifying that there was equal material on both sides of the centerline, then marking the middle with a pencil. The bolsters should be 5 scale feet from the end of the car, hopefully in the middle of the kit bolster. After using a sharp probe to make a dimple, a #50 drill was used to drill through the bolster and floor, cleaning out the resin spirals as I went. This was followed by tapping for a 2-56 screw. The resin is soft enough that no lubricant was needed.

This photo also shows the Kadee #78 couplers and near scale draft gear boxes that will be used, although I will wait to mount these until after everything is set with the floor fit . The mounting lug at the back of the box will be removed and I will also check the coupler box overhang at the end of the car to reach six scale inches. After tapping the bolsters, I temporarily installed 3/16” long 2-56 screws so that I could continue with my floor fit check.

Putting the floor back in, I discovered that it is still just slightly long and will need more careful sanding to reduce the length, as you can see on the left side in this photo. The floor width seems just right. I also noted that the floor fits just too deep into the body on the right. On the left side additional checking shows that it is about right when the floor is fully engaged on that end. I may shim the right end to bring the floor closer to flush with the sides and end of the body.

That’s my progress for now, and with Christmas upon us, will take this back up at the end of the week for my next installment.

Sunday, December 1, 2024

Building a Resin Kit - PRR X37 Boxcar

For this first resin boxcar build, I’m going into somewhat deeper detail on the steps involved than one might typically see online, in hopes that the information may be useful for others just getting started, like me.

In some respects, modern resin freight car kits are similar to styrene kits, containing a one piece carbody, a floor, or underbody, and various detail parts that are added. They differ in that they are all unpainted and usually require the modeler to furnish some items, such as trucks or styrene shapes and wire, and possibly decals or brake components also. The construction steps are similar, although sometimes more involved. Many who build resin kits will also do some research to customize the model for their modeling era or to match a specific prototype variation. This aspect is one that I find enjoyable.

There is a great variety of prototype information available, both printed and on the internet. This is worthy of its own post in the near future. Kit instructions range from the greatly detailed to cursory, depending on the source. It is worth the effort to do some searches online or to look for information and photos in reference books and magazines, if they are available to you.

After unboxing the kit and inspecting the pieces provided, it is a good idea to read through the instructions a time or two to familiarize yourself with the assembly steps. Before you do that, you may want to wash the resin components to rinse off mold release agents and read at your leisure while the parts dry. Dawn dishwashing detergent is frequently recommended, because it does not contain oils or additives such as lanolin that can cause issues when painting. Shout is used by some. You want a product that will clean off the parts without leaving its own residue behind.

I used a plastic food take out container and a soft bristle toothbrush to gently clean all the resin parts thoroughly before rinsing with cool water. Then I patted them dry with paper towels and set them aside to finish air drying while I read over the kit instructions. Now is the time to be sure you have any needed parts that are not in the kit, or to plan for substitution of kit parts if you wish. Common examples are brake components and ladders. I will point out several examples as the kit build progresses.

First off, I needed to get trucks, which were not included. My research online indicated that most of the X37 cars were equipped with PRR 2D-F19 coil elliptic trucks, as mentioned in the previous post. In HO scale, there are examples of similar trucks available from Tichy and Bowser. It seemed to me that the Bowser 40194 PRR coil semi-elliptical freight trucks had an appearance closest to the prototype, so I ordered a set.

I model 1965, so I also needed to consider the appearance of theses cars in my time frame. The decals in the kit were for the as built Circle Keystone lettering scheme. My research indicated that the cars had been repainted in the Shadow Keystone scheme by my modeling year. Microscale offers a decal set 87-1201 that should provide what I need, and was ordered.

Once the major kit parts had dried, I inspected the body for flash (excess resin from the molding process). This carbody has a fair amount of flash, including 32 “vent gates”, which are small rectangular tabs around the inside of the body near where the floor fits, as shown below.

These all have to go. I had not seen this before in other resin boxcar kits in my stash so was a bit confused at first. Some friendly folks at resinfreightcarbuilders.groups.io , an online modelers group, confirmed that I did indeed want to trim these nubs off so that the floor will fit. After a bit of pondering, I decided to use a micro saw and nippers, followed by chisels and sanding. The JLC micro saw and Xuron sprue nippers did a nice clean job with the bulk of the gates.

You will note the N95 mask, which is good practice to wear when producing resin dust, as it can be an irritant and even toxic if inhaled in significant amounts. The trimming was followed by my 2.5 mm wide Godhand chisel blade in a short handle to shave down most of the remaining material.I have written about this tool previously. You can find that post using the keywords on the sidebar. This is one of my favorite tools, very versatile, with a range of chisel shapes.

Final clean up of these gates and the other thin flash on the sidesills was done with a #11 Exacto blade and several sanding sticks, ranging from 240 to 600 grit. This work required patience and use of a magnifier to be sure it was flash and not part of the body being trimmed. The body cleaned up nicely. I was pleasantly surprised in working with the resin material. In some ways, it seems more workable than styrene. I did end up with a small notch in one of the side sill tabs, whether from an errant chisel or exposing a bubble in the resin, I do not know. Squadron Green putty was used to fill it, followed by sanding once cured.

-

Here is some background and detail on what my modeling and interests in model railroading are about. In my first post, I described my model...

-

The Northwest has a long history of forest products production, from timber and plywood to paper, providing many carloads of revenue for th...

-

A Portion of The Kit Stash Like many model railroaders, I have accumulated a large number of freight cars and locomotives over the years. ...